Learn about VCI

FAQ's about VCI

What is VCI?

VCI is an abbreviation for Vapor Corrosion Inhibitor. (Also known as VpCIs or Vapor phase Corrosion Inhibitors.) These corrosion inhibiting compounds release molecules into the air. When these compounds come in contact with metal surfaces they form a very thin molecular layer. This thin layer effectively inhibits corrosion on the metal surface by preventing air and moisture from coming in contact with the surface. Unlike other methods of rust prevention, the corrosion inhibiting vapors have the ability to reach into intricate surfaces that would be otherwise hard to reach with traditional rust prevention products.

Will I notice a film on my items?

No, you will not see or feel any film on your items. The film left by the emitter is only a few molecules thick (1/500,000 of 1 mil).

In what situations will VCI work effectively?

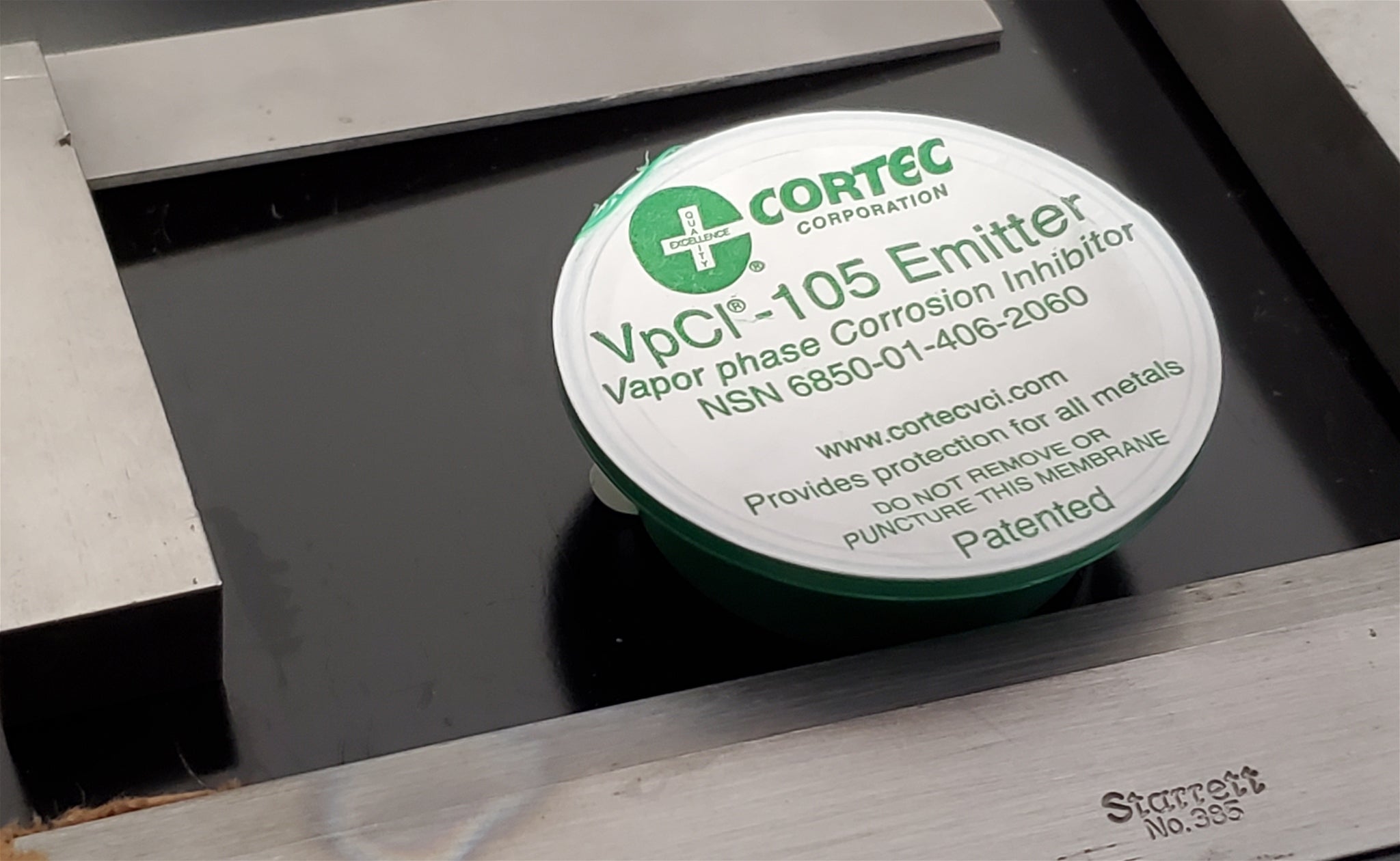

The VCI technology works on items in an enclosed area. The enclosure can be as simple as a bag, box, or any type of sealed enclosure. VCI products work in different size enclosures. We stock the full-line of Cortec VCI products as well as Bull Frog VCI Emitters, a consumer line of VCI products. VCI can protect enclosures as small as a small bagto as large as 100 cubic feet. (Larger areas can can be protected by combining multiple emitters.)

What types of items can VCI emitters protect? Why should I use VCI emitters? Are VCI products safe to use? How will I know when the VCI emitter is "used up"? How long does it take to start working? What happens to the vapors when the area is opened? What is VpCI, is it different from VCI? VCI emitters can be used to protect a variety of items from rust and corrosion. The list below represents some commonly protected items.

VCI emitters can be used to protect a variety of items from rust and corrosion. The list below represents some commonly protected items.

VCI emitters will save you time and money. They replace petroleum-based rust preventatives and save time and labor involved with applying and removing conventional protective coatings. There is no degreasing, scraping, cleaning or further preparation needed. VCI emitters can extend the life of equipment, prevent system failures, preserve the attractive appearance of products, and more.

VCI emitters contain chemicals that are not known to be hazardous, toxic, or flammable. In fact, the emitter chemicals have been approved by the United States Food and Drug Administration (FDA) to be used with food and beverage containers.

At a minimum the emitters should be replaced every two years. If the area is not air tight due to air leakage or frequent opening and closing, we would recommend replacing the emitter once a year. If you notice signs of corrosion beginning before that time, replace the emitter immediately.

The VCI emitters start work immediately when taken out of the sealed package. However, depending on the size, shape and temperature of the area, it may take up to 24 hours for all metals to become saturated with the VCI vapors.

Some of the vapors will escape when the enclosure is opened, but the VCI barrier already on the metal will not be disturbed immediately. As soon as the container is closed again, the VCI vapors will fill the area.

VpCI refers to VCI products made by Cortec. While all VpCI is VCI, only Cortec VCI is VpCI. VpCI refers to Vapor Phase Corrosion Inhibitors.